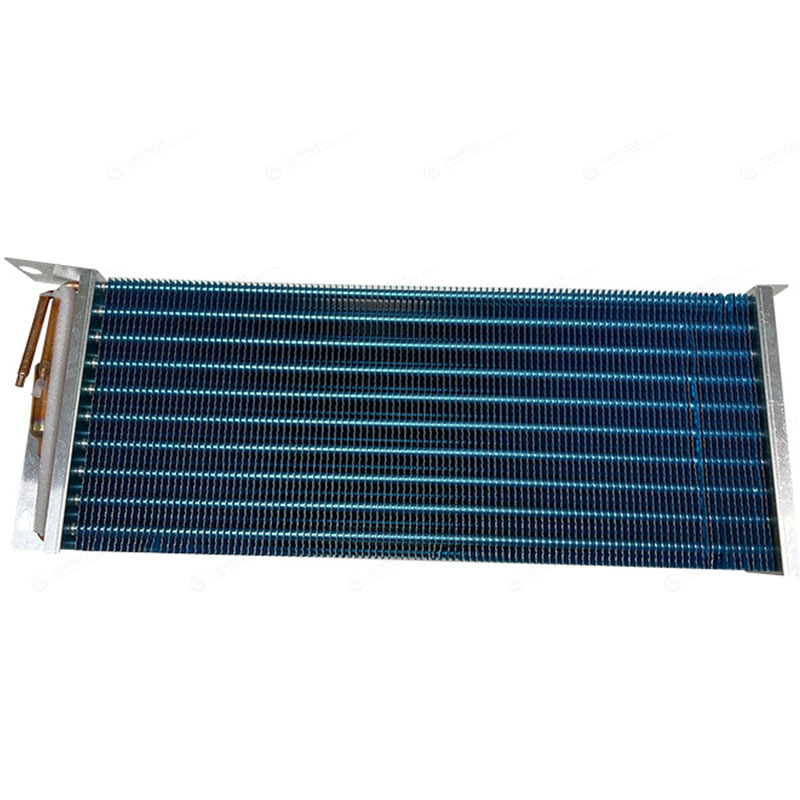

In the fields of refrigerators, cake display refrigerators, ice cream freezers, and other cooling applications, the evaporator serves as the core component for "heat exchange," directly determining the cooling efficiency and operational stability of the system. Among various types, finned evaporators have become one of the most widely used due to their unique structural design and outstanding performance. By adding fins to the surface of metal tubes (tube cores), they overcome the limitations of traditional bare-tube evaporators, demonstrating significant advantages in heat transfer efficiency, spatial adaptability, and environmental tolerance. These features provide crucial support for the miniaturization and high-efficiency development of various cooling equipment.

In addition, many devices of brands like nenwell also use finned evaporators, and their performance is good.

I. Basic Understanding: Structure and Working Principle of Finned Evaporators

To comprehend the advantages of finned evaporators, it is essential to first understand their basic structure and operating principle. The core consists of two parts: the "tube core," typically made of copper, aluminum, or copper-aluminum composite tubes, through which refrigerants (such as R32, R410A, etc.) flow. Inside the tubes, the refrigerant absorbs heat through a phase change from liquid to gas. The second part is the "fins," usually made of thin aluminum alloy sheets, which are closely attached to the tube core surface through welding, tube expanding, or winding processes, forming a dense heat dissipation/absorption structure.

During operation, the refrigerant inside the tubes evaporates and absorbs heat, lowering the temperature of the tube core. External airflows (usually driven by fans) pass through the gaps between the fins, coming into contact with the cold fins and tube core. The heat is then absorbed by the refrigerant inside the tubes, reducing the temperature of the airflow and ultimately achieving the "cooling" effect. The presence of fins is the key difference between finned evaporators and traditional bare-tube evaporators, and it is the source of many of their advantages.

II. Core Advantage 1: Drastic Improvement in Heat Transfer Efficiency to Meet High-Efficiency Cooling Requirements

Heat transfer efficiency is a crucial performance indicator for evaporators, and finned evaporators excel in this aspect, mainly due to the "exponential increase in heat transfer area" and "optimized flow field design."

Traditional bare-tube evaporators rely solely on the outer surface of the tubes for heat exchange, limiting the heat transfer area to the outer wall area of the tubes and resulting in lower efficiency. In contrast, finned evaporators expand the heat transfer area by adding fins to the tube core surface. Under the same tube length, the heat transfer area can be increased by 3 to 10 times. For example, with commonly used louver fins, the heat transfer area per meter of tube core can increase from 0.02㎡ (bare tube) to 0.2 - 0.5㎡. The larger heat transfer area ensures more extensive contact between the refrigerant inside the tubes and the external airflow, significantly increasing the heat transfer rate.

Moreover, the shape design of the fins further optimizes heat transfer efficiency. Currently, mainstream fin types include corrugated fins, louver fins, and serrated fins. Corrugated fins create turbulent flow in the airflow gaps, avoiding "boundary layer thermal resistance" and enhancing the heat exchange rate. Louver fins, through staggered arrangement, reduce airflow short-circuiting, ensuring that each part of the fins participates fully in heat exchange. Data shows that under the same operating conditions (such as refrigerant flow rate and airflow velocity), the heat transfer efficiency of finned evaporators is 40% - 80% higher than that of bare-tube evaporators, significantly reducing the energy consumption of the cooling system.

III. Core Advantage 2: Compact Structure, Adaptable to Diverse Spatial Requirements

In modern cooling equipment, "miniaturization" has become an important development trend. Whether it is household wall-mounted air conditioners, car refrigerators, or industrial precision cooling equipment, strict requirements are imposed on the space occupied by components. Finned evaporators perfectly meet this demand through the combination of "high-efficiency heat transfer" and "compact structure."

Since fins can significantly expand the heat transfer area within a limited tube length, finned evaporators do not need to increase tube length or diameter to enhance efficiency. For instance, for a 1.5-ton household wall-mounted air conditioner, if a bare-tube design is used, at least 3 meters of tubing is required to meet the heat exchange demand. In contrast, with a finned design (equipped with corrugated fins with a spacing of 2 - 3mm), only 1.2 - 1.5 meters of tubing is needed to achieve the same effect, reducing the overall volume by 30% - 50%. This compactness allows it to be easily integrated into confined spaces. The evaporator of a car air conditioner can be installed under the dashboard, the evaporator of a commercial refrigerator can be integrated into the side wall of the cabinet, and the cooling evaporator of industrial precision equipment can even be embedded inside the equipment without occupying additional space.

In addition, finned evaporators feature strong structural flexibility and can be customized in shape according to different application scenarios. Examples include the "U-shaped" evaporators for household air conditioners, the "snake-shaped" evaporators for automotive air conditioners, and the "flat-plate" evaporators for cold chain equipment, further enhancing spatial adaptability.

III. Core Advantage 3: Strong Anti-Frosting Ability, Adaptable to Low-Temperature and Humid Environments

In low-temperature cooling scenarios (such as refrigerators, freezers, and low-temperature cold storage), the surface of the evaporator is prone to frost formation as water vapor in the air condenses upon contact. Frost layers can obstruct airflow, reduce heat transfer efficiency, and even cause the system to shut down. However, finned evaporators possess enhanced anti-frosting and defrosting capabilities through special structural designs and material treatments.

From a structural design perspective, the fin spacing of finned evaporators can be flexibly adjusted according to operating conditions. In low-temperature and high-humidity environments (such as cold storage with temperatures below -18℃), the fin spacing is usually designed to be 8 - 12mm to prevent rapid frost accumulation from blocking the airflow channels. In normal-temperature cooling scenarios (such as air conditioners with temperatures above 5℃), the fin spacing can be reduced to 2 - 3mm, balancing efficiency and frost prevention. Additionally, some high-end finned evaporators adopt a "staggered fin" design, making it difficult for the frost layer to form a continuous mass, facilitating subsequent defrosting.

In terms of material treatment, the surfaces of modern finned evaporator fins are often coated with "hydrophilic coatings" or "anti-frost coatings." Hydrophilic coatings enable condensed water to quickly form a water film and flow down the fins, reducing the residence time of water vapor on the fin surface and thus lowering the probability of frost formation. Anti-frost coatings (such as polytetrafluoroethylene coatings) can reduce the adhesion between the frost layer and the fins, making it easier for the frost layer to fall off during defrosting without the need for frequent manual cleaning. Experiments show that finned evaporators with anti-frost coatings have a 60% longer frost cycle and a 30% lower defrosting energy consumption compared to ordinary finned evaporators.

IV. Core Advantage 4: High Cost-Effectiveness, More Economical for Long-Term Operation

From a life-cycle perspective, although finned evaporators have slightly higher initial design and manufacturing costs compared to bare-tube evaporators, their characteristics of "low energy consumption" and "low maintenance" can significantly reduce the total cost during long-term operation, offering higher cost-effectiveness.

On one hand, low energy consumption leads to direct electricity cost savings. As mentioned earlier, finned evaporators have higher heat transfer efficiency. For a cooling system with the same cooling capacity, the compressor operation time of a system equipped with a finned evaporator can be reduced by 20% - 30%, and energy consumption can be decreased by 15% - 25%. Take a commercial refrigerator as an example. If it operates 20 hours a day with an electricity price of 0.6 yuan per kilowatt-hour, using a finned evaporator can save approximately 800 - 1200 yuan in electricity costs annually, far exceeding the initial additional manufacturing costs.

On the other hand, maintenance costs are low, and the lifespan is long. The fins of finned evaporators are mostly made of corrosion-resistant aluminum alloy materials, and they are tightly bonded to the tube core through the tube expanding process, making them less prone to loosening or leakage. Additionally, their simple structure only requires periodic cleaning of dust in the fin gaps with a high-pressure water gun (to prevent blockage), without the need for complex disassembly. In contrast, if a bare-tube evaporator experiences tube corrosion or leakage, the entire tube section needs to be replaced, resulting in higher repair costs. Typically, the service life of finned evaporators can reach 10 - 15 years, 3 - 5 years longer than that of bare-tube evaporators.

V. Application Scenarios Expansion and Future Development

The numerous advantages of finned evaporators have enabled their extensive application in various fields. In the household sector, they are the core components of wall-mounted air conditioners, standing air conditioners, and refrigerators. In the commercial sector, they support the operation of supermarket freezers, cold chain transport vehicles, and central air conditioning systems. In the industrial field, they provide cooling for electronic devices (such as data center server cooling), machining, pharmaceutical cold storage, and other applications.

As cooling technology evolves towards "high efficiency" and "low carbon," finned evaporators are also continuously being upgraded. First, material innovation involves the use of new aluminum alloy composite materials to further enhance corrosion resistance and thermal conductivity. Second, structural optimization is achieved through numerical simulation technology to design more rational fin shapes and spacings, reducing airflow resistance. Third, integration with intelligence includes installing temperature and humidity sensors on evaporators to monitor frost conditions in real-time and enable automatic defrosting, further reducing energy consumption.

Through the core design of "expanding the heat transfer area," finned evaporators have derived multiple advantages such as high heat transfer efficiency, compact structure, strong anti-frosting ability, and high cost-effectiveness, becoming indispensable core components in the cooling field. They not only meet the current cooling requirements of various equipment but also lay the foundation for the low-carbon development of future cooling technologies. With growing emphasis on energy conservation and environmental protection, the application value of finned evaporators will become even more prominent, continuously driving the cooling industry towards greater efficiency and environmental friendliness.